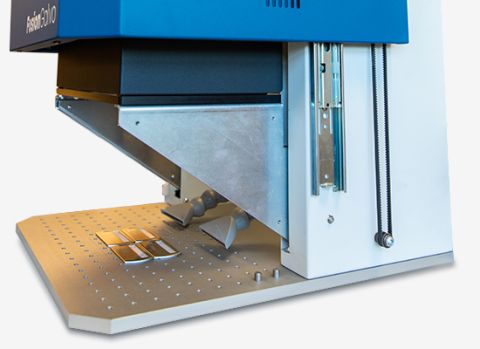

Machines laser Fusion Galvo

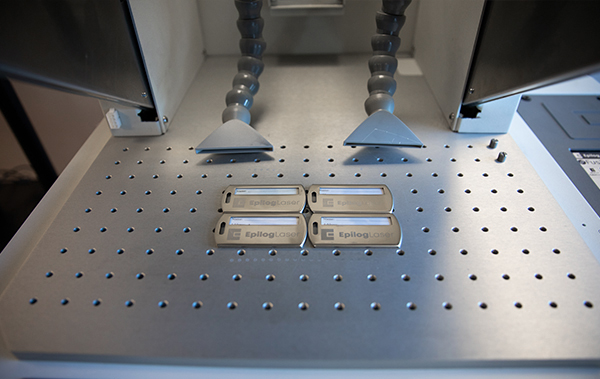

Marquage à grande vitesse grâce à une technologie de caméra sophistiquée.

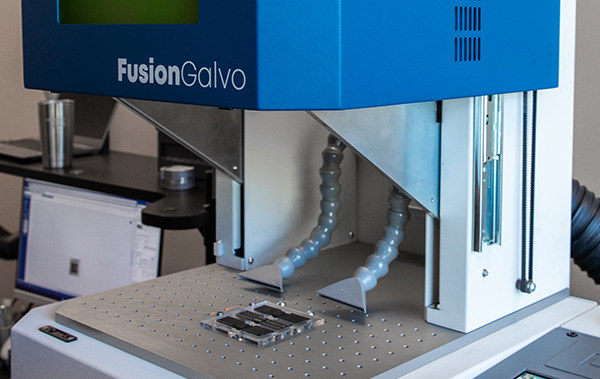

FUSION GALVO G100

Machine de marquage des métaux

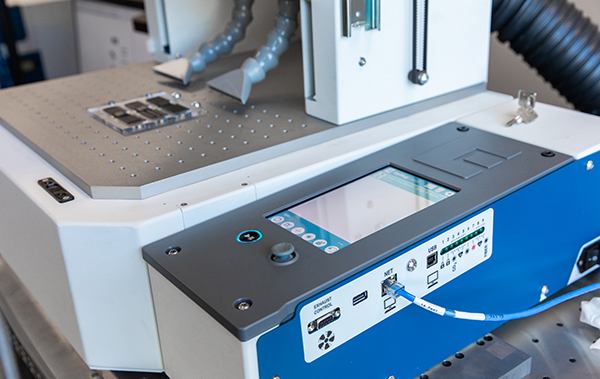

Le Fusion Galvo permet de graver rapidement des métaux et de configurer facilement vos projets. Cette machine laser innovante permet de réaliser différentes gravures sur le métal, notamment des gravures profondes, des marques blanches polies et des gravures recuites profondes de couleur noire. Configurez facilement votre projet à l'aide du tableau de bord laser d'Epilog et placez très précisément vos motifs grâce au système de caméra IRIS™. Ce laser dispose également d'une interface particulièrement conviviale et est fabriqué avec des composants de haute qualité, ce qui vous permet d'obtenir des résultats inégalés.

Regardez de plus près :

Demander Échantillons Gratuits et Informations

"*" indique les champs obligatoires

Ce site est protégé par reCAPTCHA et la Politique de confidentialité de Google ainsi que les Conditions générales s’appliquent.

Pas de programmation compliquée

Deux lentilles, deux caméras, deux choix de champs

Une porte automatisée pour changer rapidement les pièces

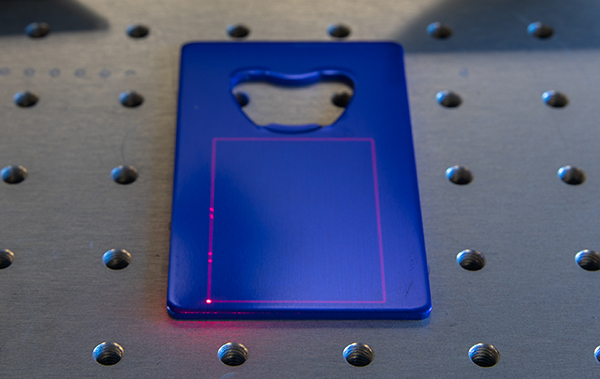

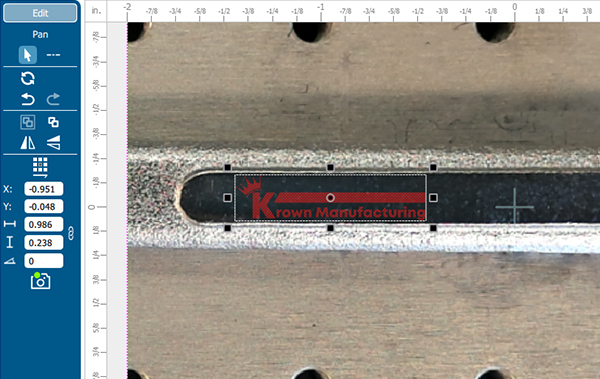

Un système de positionnement précis

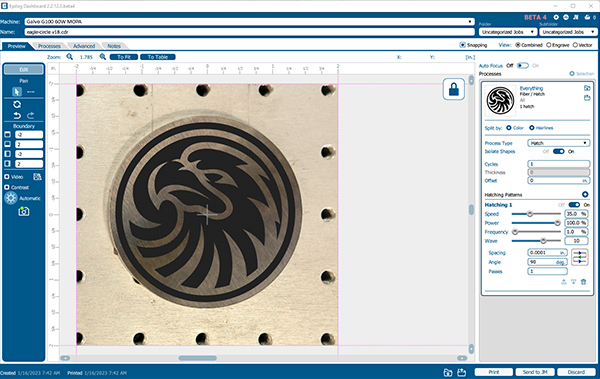

Configuration du projet Galvo

FONCTIONNALITÉS Fonctionnalités : améliorations de la machine destinées à augmenter la productivité

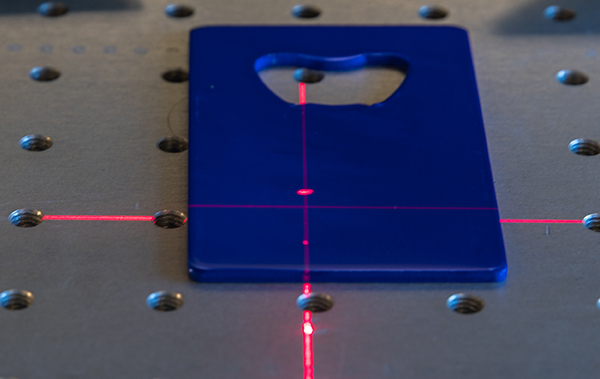

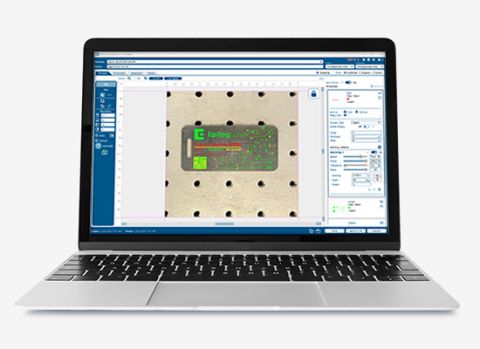

Le système IRIS™ de positionnement de la caméra

Une caméra située sur la porte d’accès supérieure permet d’obtenir une vision en temps réel de la surface de travail, et donc de positionner les motifs de manière précise. Le motif est placé par glisser-déposer à l’écran pour un traitement plus rapide.

Boussole

Récepteur inférieur

AR

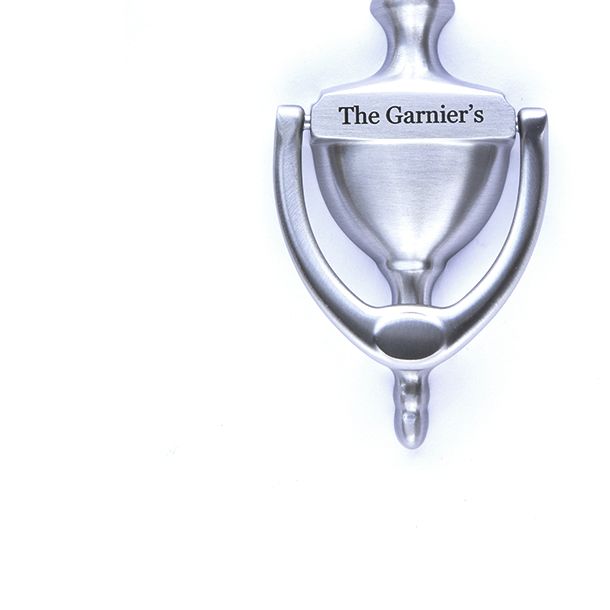

Heurtoir

de porte

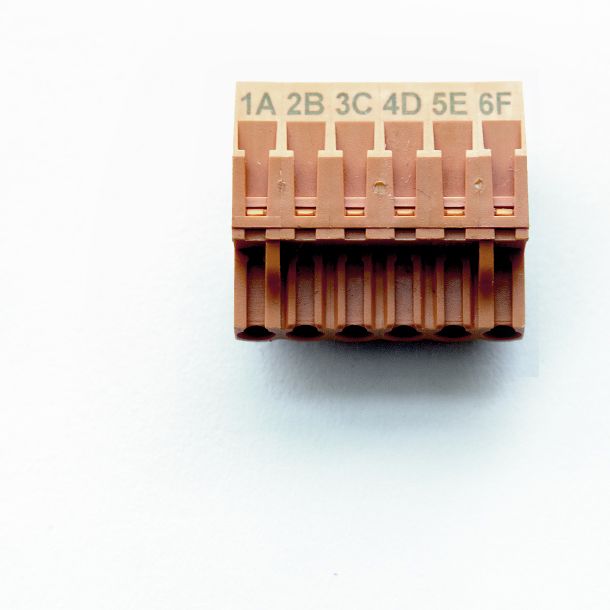

Connecteur

Pinces

Récepteur inférieur

AR

Pinces

Pièce de monnaie en forme d'aigle

Anneau en métal

Gamelle

Magasin

AR

Clé à molette

Dessous de verre

Compatibilité des matériaux :

Avec le Galvo Fusion, vous pouvez marquer une grande variété de métaux et de plastiques usinés.

| Acier inoxydable 17-4 PH | Acier inoxydable 303 | Acier 4043 | Aluminium 6061 |

| ABS (noir/blanc) | Aluminum, 6061 | Aluminum, chromé jaune | Polycarbonate en Makrolon Bayer 2807 |

| Bayers bayblend FR110 | ABS noir/blanc | Polycarbonate noir/blanc | Laiton |

| Aluminiun brassé | Nanotubes de carbone | Céramique, plaqué métal | Aluminium anodisé à revêtement transparent |

| Acier au chrome cobalt | Delrin coloré (noir/marron) | Poudre de fer compact avec revêtement fer-phosphate | Cuivre |

| DAP - phtalate de diallyle | Delrin, coloré (noir/marron) | Résine de polycarbonate GE Plastics 121-R | PEEK chargé verre |

| Teflon armé de verre | Aluminium anodisé à revêtement dur | Métaux Inconel (divers) | Acier machine-outils |

| Magnésium | Céramiques plaquées métal | Molybdène | Acier doux 1215 plaqué nickel |

| Laiton plaqué nickel | Or plaqué nickel | Kovar plaqué nickel | Acier plaqué nickel |

| Nylon | PEEK, blanc | Polyéthylène téréphtalate | Polycarbonate (noir/blanc) |

| Résine de polycarbonate 121-R, plastiques GE | Polycarbonate, Makrolon Bayer 2807 | Polysulphone | Rynite PET |

| Santoprene | Carbure de silicium | Fer silicium | Plaquettes de silicium |

| Acier inoxydable 303 | Acier inoxydable 17-4 PH | Acier 4043 | Acier, machine-outil |

| Divers métaux Inconel (super alliages nickel-chrome) | PEEK blanc | Aluminium chromé jaune | Acier doux zingué |

| Et bien d'autres ! | |||

spécifications techniques Machines laser Fusion Galvo

Machine laser : |

FUSION GALVOMachine de marquage des métaux

|

Surface de travail : |

F163 : 101 x 101 mm ; F254 : 152 x 152 mm |

Épaisseur des matériaux : |

F163 : 254 mm ; F254 : 152 mm |

Source laser : |

Fibre, refroidissement à l'air, 1064 nm |

Consommation en watts de la source laser : |

Configurations de laser à fibre pulsé de 30 watts, MOPA de 30 watts ou MOPA de 60 watts |

Système par caméra IRIS™ : |

2 caméras aériennes |

Compatibilité logicielle : |

fonctionne avec la plupart des logiciels de CAO et de conception sous Windows |

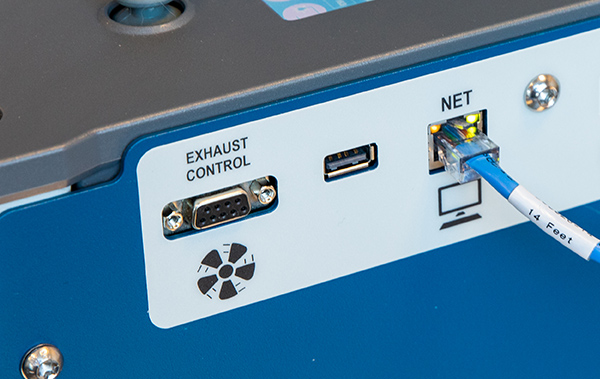

Connectivité sans fil : |

Fonctions comprises |

Lentilles incluses : |

Objectif F163 et F254 |

Résolution : |

Entièrement flexible et commandée par l’utilisateur de 75 à 1 200 ppp. |

Pilote et logiciel d’impression : |

Laser Dashboard™, Epilog Job Manager™ |

Mémoire interne : |

Stockez plusieurs fichiers jusqu’à 1 Go. Gravez des fichiers de toutes les tailles. |

Ventilateurs de refroidissement Super-Silent : |

Fonctions comprises |

Job Trace : |

Fonctions comprises |

Auto Focus : |

Fonctions comprises |

Écran tactile : |

Fonctions comprises |

Poids maximal de la table : |

182 kg (400 lb) |

Dimensions (L x P x H) : |

28" x 23" x 31" (porte fermée) 37" de hauteur (porte ouverte) 711mm x 584mm x 787mm / 940mm |

Poids : |

131 kg (59.5 lb) |

Alimentation électrique : |

Commutation automatique 100 à 120 volts, consommation maximale : 13 A Commutation automatique 220 à 240 volts, consommation maximale : 6,5 A 50 ou 60 Hz, monophasé |

Ventilation : |

450-650 CFM (764-1104 m3/hr) |

Classe |

Produit laser de classe 2 - 1 mW cW maximum 600-700 nm |

Demande d'informations supplémentaires

Demande d'informations supplémentaires

et obtenez plus d'informations de votre distributeur local.